As you may know, we offer sandblaster nozzles with longer lasting steel ball valves or offer the steel ball valves sold individually here. Although these steel valves will last longer than typical brass valves, they will still get ruined quickly if not used correctly.

Unfortunately, even these steel valves and their internal seals will deteriorate if the valve isn’t fully open while blasting. Ball valves are just not made to handle hard abrasives hammering on the internal components when it is halfway open. Blaster tool manufacturers usually state in their instructions that the ball valve must be fully open or closed.

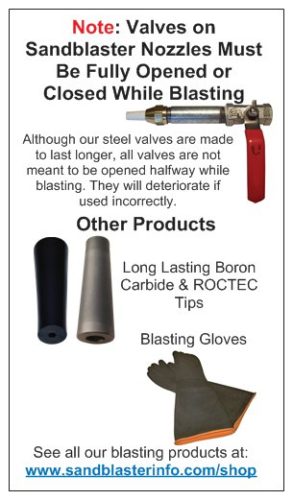

Note: Valves on Sandblaster Nozzles Must Be Fully Opened or Closed While Blasting

I occasionally get a customer advising that the valve wore out quickly, and I soon discover that they had it halfway open while blasting.

I have provided the warning note card shown here with every order for the past year or so which states:

Although our steel valves are made to last longer, all valves are not meant to be opened halfway while blasting. They will deteriorate if used incorrectly.

Although this note has helped many folks, some are still using these incorrectly.

It is my hope that this post will be educational for you and to help clarify the importance of having a ball valve fully open while blasting.

To add, I will now include the below sticker with the note on all orders going forward for all our sandblaster valves. This will make it easier to see and prevent damage to their valve.

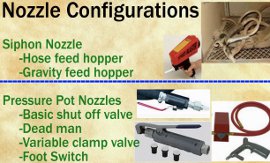

Ball Valves for Pressure Pot Sandblaster: Nozzles Vs. Abrasive Metering

Example of Abrasive Metering ball Valve.

Ball valves are meant to be used simply as an ON or OFF device, not for reducing the amount of abrasive coming out of the nozzle.

However, most of us, including myself will use ball valves partially opened for abrasive metering below the pressure pot. The abrasive metering ball valve is the ball valve directly below the pressure pot. Since this area doesn’t handle as much stress as the nozzle’s valve does, it is usually okay to adjust the abrasive to air ratio here by having it partially open.

The abrasive metering ball valve will still wear out when used partially open while blasting but is not as significant. It will have to be replaced occasionally and I like to upgrade them to steel valves once the brass valve wears out.

How to Adjust Amount of Abrasive & Air Coming Out of Nozzle Correctly

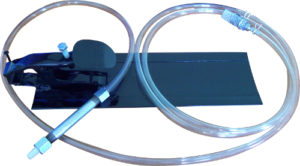

Favorite method that I still use today.

The reason most folks open the ball valve on their nozzle halfway is because they want to reduce the amount of abrasive and air being blasted out of it.

You can reduce the volume of abrasive to some extent by adjusting the amount of flow coming from the abrasive metering valve and the air valve going to the bottom tee. However, this can be quite the pain to mess with. The below methods will further help:

- Variable Footswitch Valve: The best way I have found to control the amount of blast out of the nozzle is to use this footswitch that I make.

- Variable Hose Clamp: Also called a pinch valve, these work the same way as the above, (although not as comfortable). I provide a kit which includes it on Amazon here. A lot of times, I like to use the ball valve nozzle with either of the two above methods.

- Use a smaller Inner Diameter nozzle tip such as a 3/32″ or 1/16″

- Reduce the sandblaster hose size. I provide kits with a smaller 1/4″ ID hose. Most sandblasting, especially us glass etchers don’t always need higher volumes.

What is Your Method for Adjusting Sandblast Volume at the Nozzle?

I would like to hear from you in the comments below and see how everyone else adjusts the amount of abrasive and air coming from their nozzle. Please feel free to ask any question also.

Share this on social media or email by clicking below!

I have tried every combination of ball valves and foot valves. For me, the PAB Blaster gun is the best solution. Total control, long lasting, and simple maintenance.

@ Len, that is a great solution- you can’t go wrong there. I have made my own version of that in the past. Thanks for sharing

Hello Eric

I have a few new parts available

10 packs of ceramic nozzles,

1 air eraser, used twice,

1 dead man

These are all new, not useful to me at this stage, (I use both boron sizes 1/16 and 3/32, have for a few years)

I bought an master blaster dual tanks form Eastwood I have tried different medias in cannot get no pressure at the nozzle tip, it puts out plenty crushed glass but no pressure behind it, any help will be appreciated,I call tech at Eastwood ,they said I must have a blockage,I took it all apart cleaned out all the lines to no avail. Carl.

How much 80 grit Aluminum Oxide material is needed to glass etch a 6”x 6” stencil

Can 80 Grit Aluminum Oxide that has been used be collected and re-used?