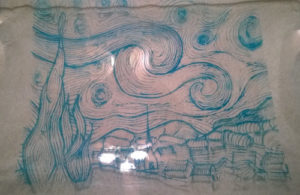

One of her projects was using a high speed engraver to carve through a ceramic mug, as seen on the left. Many mugs like this have a colored glaze coating which reveal a white ceramic material once engraved. The contrast of white against a colored glaze makes designs really pop out and is different than the typical printed mug. Much cooler in my opinion!

I’ve never tried rotary engraving rocks, but she shared this project also for breast cancer awareness. Engraving larger rocks would probably be easier to do with the sandcarving process, but I think rotary engraving would be great for smaller, fine grain stones. Another idea to think about.

Cheryl also shared the below details:

I sand blasted the plate with pencil sand blaster and colored it using pinata colors. I used photoresist for the design. I hand carved the rock using a dremel used rustoleum paint for color and pencil blasted and hand carved with 400sx carver.

Please leave Cheryl some comments or questions below. Thank you, Cheryl!

Share this on social media or email by clicking below!

Cheryl, thank you for sharing your art with all of us! I don’t normally ask about equipment used, but what brand/model of pencil sandblaster did you use for the clear glass plate? I really need to change up some equipment. There’s so much available, but I can’t afford to waste money on junk. TIA.

The coffee mugs turned out awesome. I’m sure these will last longer than conventional printed mugs and stand out more as well.

Great out of the box thinking! Would be hard to do a full scale production of the mugs you created in this fashion but I believe the way you created these mugs make them even more special. For anyone who creates mugs like this using sandblasting or engraving should note that you may want to apply a clear coat over the areas where the colored surface has been removed. I learned very quickly that these areas will get stained by whatever it gets in contact with (Coffee, Juice, Dirty hands, ect). Nice work on the stone and glass panel as well. I do enjoy seeing the other people’s creations! Keep on Keeping on!

Thanks its and a good idea

What kind of a high speed engraver did you use?

@Robin, according to what she sent me, its the 400sx carver which I believe is a product made from SCM.

@Dan of Suna Custom, great tip! Thanks for sharing

Donna I use pencil bottle Blaster from Etchworld.com. I have found it is the cheapest and with minor repairs lasted me over 7yrs. I use the carbide tip and only uses 220 grit. It requires mastering but fast to use when have a qick job to be done. On the Stone I used a dremel with Carbide bits cuts limestone like butter. The limestone was extrmely fragile that is why i hand carved it plus just to see if I can and share to others.

Thanks for the inf Cheryl. I really appreciate it!