A sandblaster functions by spraying a fast moving stream of abrasive particles out of a nozzle, which is all powered or forced by a source of compressed air. An air compressor is needed to supply the compressed air to the sandblaster. To explain in more detail, an air compressor is connected to the sandblaster setup by an air hose to supply the system with the force to blast the abrasive media.

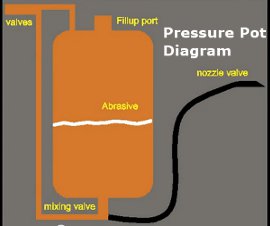

Depending on the type, the setup is configured by a specific holding tank for the abrasive particles, and another hose connects it to the nozzle. The air compressor is configured to the system a certain way to provide the power, but it depends on the type.

The two types are:

- Siphon Sandblaster

- Pressure Pot Sandblaster

Selection: Siphon vs. Pressure Pot

Basically, these 2 types can both be used for etching with different positive and negative characteristics. You may desire one or the other or maybe even both, as most glass artisans would enjoy. I will show you a solution where you can combine both types together later on in the next upcoming posts.

Share this on social media or email by clicking below!