FAQ

This section is for anyone to post a question in the comment section for those who ordered the instruction book or for those just looking for more information about etching glass. But hold on, this isn’t limited to glass, its also for a discussion about sandcarving other items as well such as wood, metal, stones or large rock, or whatever you personalizing. With the sandblasting processes that I showed and explained to you, there is nearly unlimited objects that you can work with.

So to help many people, then they can ask questions here. This way everyone can see the questions and answers in one place, because some people may have the same questions.

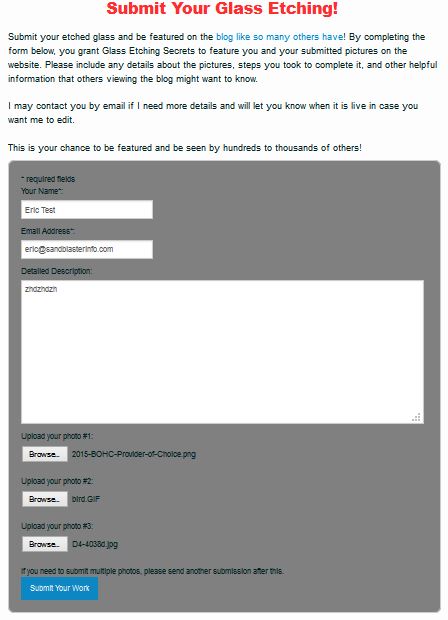

Update: If you haven’t signed up for my new Membership site, you can still be part of the community by sharing your projects here.

Share this on social media or email by clicking below!

Hi Eric

I grabbed your manual as I wish to buy a low-cost yet effective glass sandblasting set-up.

I am in the UK, so your Harbor Freight recommendations don’t apply to me.

I was wondering, if you have a moment, could you take a look at these bits, please? Just to see whether you think they would do the trick:

I’m looking at this pressure pot:

http://www.machinemart.co.uk/shop/product/details/clarke-cpsb100pressurised-sandblaster

with this cabinet:

http://www.machinemart.co.uk/shop/product/details/heavy-duty-blast-cabinet

and this compressor:

http://www.machinemart.co.uk/shop/product/details/airmaster-tiger-14-60-air-compressor/path/airmaster-2

The specs seem to agree with each other as far as I can see, though my main area of concern is the compressor. It is the largest of the ‘DIY’ compressors available, and after this the spec jumps to an ‘industrial’ compressor and the price leaps from $428 up to $820.

Here is the next one up, the $820 one:

http://www.machinemart.co.uk/shop/product/details/se15c150-ol-air-compressor/path/professionalindustrial-air-compressors-elect

It looks much more the part, but sadly I can’t afford it.

Do you think the cheaper one might keep me going, perhaps for a while until I can get something better?

Cheers for the manual, there is some very useful advice in there.

Jackie

Great questions Jackie. The first link to the pressure pot is a decent size and I heard it is basically the same thing as the harbor freight one that I suggested. If you have abrasive flow problems, be sure to check the exclusive bonuses that I give you. It will help alot.

The cabinet looks good to start with, but the bigger, the better. The more space you have inside, not only allows for larger glass, but also doesn’t cloud up as quick. If you have little space, a small sandstorm will be clouding up the cabinet, making it hard to see. Either way its a great place to start and should probablly be used with a vaccum filter.

Now compressors can be complicated because it depends on stuff like the hose & nozzle size and the air pressure. Bigger is always better, but if the air compressor meets the requirements of the sandblaster then you should be good. A bigger one will usually last longer since it won’t be running as much.

Another suggestion is to buy a smaller sandblaster hose if you aren’t blasting/ sandcarving large items like outdoor rocks. A decent size would be about 1/8″ ID (Inner Diameter) for typical glass etchings.

If you have anymore questions, be sure to place them here. I hope this helps.

Thanks, Eric for the advice. I thought a bit more about the compressor. Due to the space, I am limited to a 50 litre tank, so as it could be going quite a lot I decided to go for a belt drive which should run cooler and last longer. I am also limited by the power supply, which is basic 13 amp domestic – it would be difficult and expensive to run a dedicated 30amp supply to my workshop. So in the end, my choices where whittled down to the only 3HP compressor that will run on 13amp:

Got a good deal on ebay on one which had been used for instore demos, which still has the full guarantee on it.

Not planning to blast any rocks, so I will keep your hose tip in mind, as the cabinet says it needs 10 cfm and the compressor has a 9.9 cfm free air delivery. I envisage using the pressure pot more than the cabinet’s siphon system, so figure that slight difference won’t affect me too much.

I’ve ordered it all today so in a week or so, will know if it all works together! The pressure pot mod looks useful, I will talk to my engineer son about that little job…

Wish me luck!

Great, I hope it all works out Jackie and be sure to ask any questions if you get stuck on anything. And yeah the power supply can be a problem for people.

The pressure pot should use less air and using a smaller hose will help.

Feel free to keep in touch.

-Eric

I am having a bit of a vacuume problem, not keeping my cabinet as clear as I’d like.

Probably to small so was wondering what would be better.

I like to keep the exhaust or tailpipe if you like in a filter also so I can see how much I’m keeping inside the vacuume and not entering my workroom.

If you can email me to the above address that would be great.

Thanks loads.

Hi Eric, I know that you said that the creation brand is a better deal , is there another brand that is ok or are most of the rest of the low end vinyl cutters not worth the investment? Thanks

Roy, there are a few other inexpensive brands out there that might be decent but haven’t tried them. I have done some research and found that some of the others had minor problems every once in awhile.

One inexpensive one is Redsail, but I heard it had problems after awhile.

I am not sure about the others on ebay in canada, but I would look at how often your going to use it. If you are going to use it often, then you might want to look into name brands like Roland or Graphtec.

But either way, I think any inexpensive one will pay it off with the revenue received from those jobs.

You can also look at small craft cutters if your aren’t doing deeper sandcarving work.

Shortley after I got my glass etching instruction book and was looking at some other things abought sand blasting, I saw something abought blasting Pipes and making (smoking pipes) I have looked and looked but can’t seem to be able to locate any info;;;

would you please help me in this matter or was I dreaming LOL LOL

John

John, Im not too sure what you mean or trying to achieve. Can you give me more details about it?

Thanks

-Eric

Hi Eric,

I recall you were going to do a DIY build of the PAB gun but I cannot find it on your website.

Have you managed to do it yet please?

Tony, you should have got my email about it and is shown in the video: https://www.glassetchingsecrets.com/blog/techniques-for-etched-glass/

I have made this awhile back and only costed me around $15 total (I think) with the hose. I wrote out a guide with plans that I sold before and am still trying to make the DIY blaster better. I’ll be sure to let everyone know about it.

Hello Eric, I am still working on my setup. Finally got my compressor wired up. A Kobalt 60 gal. 3.7 hp SCFM 11.5 @ 90 psi. I can say I know more about breaker panels and my crash course in wiring electrical things. Nobody got hurt and my house won’t burn down with the wrong load. Glad I asked enough questions with the right people. Have the the 20 pd. pressure pot from harbor freights. Just need to put it together now. I live in the panhandle of Florida where water can be a big problem. The compressed air devises that take the moisture out of the air can be priced pretty high. I am thinking about coiling copper tubing and cooling it with air to get it to reach its dew point and have a water trap. I may just have to spend the bucks to get the water out. It’s not bad airbrushing t-shirts you can just blow it out and keep going, but from what I understand the moisture can clog me up. Do you have any ideals getting rid of my unwanted moisture? Yes moisture is my next problem to over come. Maybe a combination of things might solve it. Thanks Ron and again great book Glass Etching

Secrets. I would still be in the dark ages. Hope to be sandblasting big time soon.

Wow, I just seen a u tube thing with a PAB gun. I now know what I am going to do with the pressure pot I got from Harbor Freights that I found out about in that e-book I got awhile back Glass etching secrets. With the things I am learning and what I can hip myself to. When I airbrushed back before the days of the stencil plotting machines we had the trusty ole stencil burners ( make sure you ventilate and don’t breath the fumes)just draw, print, paste or trace your design. I like using Mylar I’m makin me a PAB gun after I get the pressure pot. Guess I’ll call it Mean Dean’s Sandblasting Machine I like learning new things. Its fun and you can turn your idea’s in to real things

Ron,

Its great to hear your making some progress getting a system setup. And yes, humidity is a problem and can clog up the sandblaster. I have seen people use the coil setup and heard it works great. What you do is bend the coil tubing around in a bucket and place ice in it. Then have your filter/separator hooked up after the air goes through it.

Let us know how your Mean Dean sandblaster goes. All the best

What do you think about the Paasche Air Eraser? I know it can etch glass, but can it do deeper (second stage) glass etching or stone etching as well? Your comments appreciated.

Rockie

Hi Rockie, the Paasche Air Eraser is only a siphon sandblaster with very low pressures so it couldn’t be used for stone carving or two stage glass etching.

You might be able to use the Paasche Air Eraser for carvings but it would take all day to get it done. You need a pressure pot to do things like this. You can find a pressure pot which only costs a little more than this, except you might need a larger compressor.

Thanks!

Any ideas on how to display round glass etchings? I just completed a 20″ round

angel fish, multi-etch piece, and when I went to drill holes so that I could hang it, the piece broke. Round frames are much too expensive, and stands, unless they’re huge, won’t hold up a large, heavy piece. Are there any other alternatives? I know, next time, I’ll drill the holes first.

Nadina, I haven’t got into glass drilling much but I do know that your pressure pot sandblaster will blast a nice hole through the glass if you turn the pressure up. I have done it a few times.

Some glass is more brittle than others also. Here is a good resource of how to do it correctly and tips: http://www.wikihow.com/Drill-Holes-Through-Glass

Thanks Eric. The site proved to be very helpful. Any other ideas from anyone for alternatives to displaying larger round glass pieces?

Hi Eric,

I purchased a pressure pot from Harbour Freight and had it sent to Australia. I use a Pab Gun and it has been good. The problem I have is that I don’t get a steady flow from the pot. Could you please advise the set up of the pot to get a consistent flow of grit.

AussieKev, I emailed you some solutions about this. I hope they help.

Hello Eric!

I got the Speed Blaster gun that you suggested and its pretty cool. But I have another question/issue. The nozzle is sorta bigger than I was expecting. I talked to Zendex and they told me they dont sell other nozzles. Do you know if theres a nozzle that could fit the gun that could be thinner for smaller finer grit?

Please let me know! Thanks in advance

Hi Beatriz, I haven’t tried every sandblaster out in the marketplace and would assume that there are different replacements available. I just checked around and I didn’t see any different size nozzles either. Thats kind of weird so if you can’t find any, you could try to fabricate one or try the ones that Harbor freight sells.

Interesting, I live in the St.Louis area and I’m having a heck of a time finding Alum Oxide. Harbor Freight seems to catty 5 lbs containser at $20 a pop(seems expensive to me). I can find it online, but shipping sometimes cost more than the product.

If anyone reads this from the area and you know of a local supplier, I would appreicate the feedback.

Is there any alternative media to etch with besides alum oxide at a reasonable cost?

Rick, I find that odd also- I just did a quick search for you also. The only place that seems to offer it in your area is a place called Fastenal Co.

If its not in stock then you might have to order it and wait a week- usually you won’t have to pay shipping if you pick it up there. Not positive on that if anyone else knows- let us know.

WOULD LIKE TO KNOW WHERE THE BEST PLACE TO GET ETHING TOOLS THAT I NEED IN MY AREA I HAVE SOME THAT WERE GIVEN TO ME AND I WOULD LIKE TO GET MORE AND DIFFRENT SIZES – I HAVE LOOKED IN ALOT OF PLACES BUT NOT MANY HAVE WHAT TOOLS I NEED TO DO A GOOD JOB – SO ANY HELP

Bought your manual and I thought it was well worth the money. Recently, I came upon a glass that had been etched with a company name on it. The letters seemed to be etched inside of a blue colored rectangle. Do you know how they got the blue coloring on there? I tried to scratch the blue area off with a knife to see if it was just a surface mounted rectangle, but my knife wouldn’t even scratch it. Any ideas on how they did it?

Bob, I am not too sure, but if you have a photo- I could tell you what I think.

Hi ERIC READING THE COMMENTS AND QUESTIONS I HAVE SOME HELP MABY I SANDBLAST IN A DARK ROOM SO THE LIGHT IN THE CABINET IS BRIGHTER ALSO I HAVE A DUST COLLECTOR HOOKED UP TO MYN CABINET WITH A BAG WHAT LET ONLY 1 MICRO TRUE i HAVE THIS FOR YEARS AND NO PROBLEMS

Hi Eric do you have any information or advice on glass etching with a dremel power tool I am new in this Hobby I got interisted after I bought your e book and thanks for a novice like me it help a great deal.

Here from you soon

Thanks

Chris

South Africa

Chris, thanks for the comment. I sent you an email about it. I hope it helps.

Do they make a blasting cabinet that you can use with a pressure pot blaster instead of a suction type cabinet

Is there such a blast cabinet that you can use with a pressure pot system

i just have took this hobby up and have done a few etching’s and decieded to by a blasting cabinet the cabinet i bought came from harbour freight and has the ceramic nozzles 4,5,6,7, mm im just curious as to which one i should use for do just a plain beer mug hope you can shed some light on this thxs and i have to say your book was very helpfull to me

@ Tyrone, ideally out of those four, the smallest at 4 mm would be best, but all could be used. In this industry its preferred to use nothing much larger than 1/8″ which equates to 3.175 mm. Smaller nozzles allow better control, especially if you are doing artistic etching and they use much less air. So you might need a larger air compressor if you want to use the larger nozzles. Also, Thanks!

@ Chuck, yes there are pressure pot sandblasters that are configured with a blast cabinet. They are nice because it makes refilling the abrasive easy, but are very expensive. I believe Ikonics Imaging has some.

How can I make a design etched with the cream stand out more. On colored glass it seems to get lost and hard to make out.

Do you know if there are any concerns with sandblasting automotive glass in cold temperatures? We just watched your video on sandblasting auto glass and are considering doing it on our truck, but it is snowing here. Do you know if we should leave the truck running in the garage while we etch the image, are there any concerns with the glass as the truck cools down?

Where are some good places to purchase glass awards blanks for etching?

Hi Eric hope the holiday season is treating you well. I am interested in the members equipment from Cincinnati,tvols1970@yahoo.com, Im not getting any responce back from him and I was wondering if this was his correct e-mail address. I have another question also: I bought your manual a while back and I lost it on my computer. (crashed) I was wondering if there was any possiblke way of getting another copy?

@Beth, the only other way is to use glass paint. Their is some type of etching cream paint available for this.

@Marie, it might be more fragile in the winter. Make sure you lightly etch it or the safety glass can shatter.

@Chuck, he probably has been getting a lot of emails about it and can’t respond to them all. I’ll send you an email about the download.

Thanks

I use photo resist film and I am trying to get a wedding invitation to etch with alum oxide on a picture frame but I keep loosing the small letters. I don’t know if I wash them out or what I can do. This film is expensive as you know. I don’t even get to the sand blasting part which is the easy part.

Peggy, I want to make sure I am on the same page. You are on loosing the small letters on the washout process, not the sandblasting process, correct?

If that’s the case:

the lettering might not be of high quality

the ink could be too light on the transparent sheet

the Ultra violet light could be set to expose too long (make sure you use the manufacturers recommended settings)

you might not be using a warm water to wash out

you might be washing out that area too long. make sure you are always moving back and forth without pausing from left to right, top to bottom in cycles (patience is key)

Or the photoresist could be expired. (they have expiration dates.) I had to throw a bunch in the trash which was a bummer 🙁

Hope that helps. You can also read my solutions here: https://www.glassetchingsecrets.com/blog/photoresist-blowouts/

Hi Eric,

I absolutely love the book. I think everyone interested in glass etching should read it before getting started.

I bought a small Paasche sandblaster and I’m considering getting a pressure pot blaster. I have a 6 gallon, 150psi, 1.5hp compressor rated at 2.6 scfm @90psi. What options do I have for a pot blaster? Or is that compressor just too small…

Thanks,

Austin

WHERE IS THE BEST PLACE TO PURCHASE STENCILS OR STICKERS FOR THE DIP N ETCH PROCESS. OR IS THERE A WAY TO MAKE MY OWN?

THANKS,

KRISTI

Eric, I saw up above one of the questions was about someone getting started and using a dremel tool for etching. I also do… You said you sent him an email on tips for this proceedure, can you send me the same email information. Thank you! Love this site, Just stumbled into it today. Looking forward to talking with you more.

Cindy

Eric

Were can I find L E D lights I can use and cut to make my oun lighted bases. I

would like them to be 110 volt AC or 9 volt DC, white, blue, or green. Operating with or with out a switch.

Iowa Sandman

Hi, im interested in your book and your tutorials, i need your contact… can you please contact me? jorgeam_u@hotmail.com

I HAVE MIX-UP PROBLEM WITH THE ORDERING PROCESS. I SOUGHT ONLY TO ORDER THE BASIC

BOOK ETC IT WAS NOT MY DESIRE TO SUBSCRIBE TO AN ADDITIONAL TWENTY DOLLARS PER MONTH UNTIL I HAD ACCESS TO AND EVALUATED WHAT WAS BEING OFFERED. I JUST ORDERED FIVE MINUTES AGO AND REALIZED THAT I HAD MISTAKENLY COMMITTED TO A PAYMENT PLAN THAT I CANNOT HONOR AT THIS TIME. IT IS MY DESIRE TO NOT CONTINUE WITH THAT PLAN

NOW. I WILL INSTRUCT MY BANK NOT TO HONOR ANY FURTHER PAYMENTS OTHER THAN THE INITIAL PAYMENT OF TWENTY ONE DOLLARS AND NINETY NINE CENTS.

THANKS,

GEORGE CAPRON

Hi George,

That would be perfectly fine. I submitted a request to the payment processor to cancel your subscription for future months so you will not be billed any further.

Thanks

A little help please. I paid the $21.99 and have no idea where to go to get the ebook and bonuses. Can I download them or how do I do what? I’m not computer literate and kinda slow. I do good at glass etch with my eraser air brush, mask,etc. because I can just sit, broke my back twice and can’t do a lot of other things I used to. Just aim my in the right direction.

Any help would be appreciated,

Rob

Eric, great videos and website. thank you very much. i have a query- i need a compressor for a 10 gal pressure blaster that requires 65-125 psi, 6.5-25 cmf respectively. in your opinion, will the Craftsman Professional 27 Gallon Super Quiet Vertical Portable Air Compressor (150 psi, SCFM delivery at 40 PSI: 7.2 SCFM; SCFM delivery at 90 PSI: 5.8 SCFM) be sufficient for it? i sandcarve glass windows once in a while- when i do, maybe 5 minutes and break for 30 -60 seconds, thank you.

Eric, I need to purchase some silicon carbide to replace my existing grit. Please advise the grit size needed to be able to do general blasting on glass with a pressure blaster. Also the size grit required for carving.

Do you know any suppliers in Australia?

@ Kevin, I know I replied to your email, but wanted to post here in case it helps others.

Sorry about the late response- been very busy lately. Silicon Carbide is still the best known abrasive for etching, but Aluminum Oxide is usually good enough also.

The grit size is usually a preference, but I like to stick around 150 grit. It’s not too fine, nor too course which is still good enough for sandcarving. Definitely stay within 120-220 range for most etchings.

It is tough to find places that will ship abrasive that far at times. If you can’t find it locally or in your country, you might have to search around online. I would suggest looking in directories in the country and calling around if any factories know where to buy it.

I hope that helps and sorry if I couldn’t be more of help. Let me know if you need anything else. Thank you!

Can anybody please tell me how to vectorize an image on Adobe CS2?

I teach 3 level sandblasting (don’t know the correct term is) at our local stained glass club. We had our equipment refurbished about 6 months ago and unfortunately I wasn’t there when this happened. I presume he asked our club president at the time if we only did “decorative” sandblasting (like on bottles at Christmas!) because he told her we only need a fine grit. The fine grit takes forever on 3 levels, not only that it is shredding the resist paper and the whole exercise is a waste of time. Now she says she cannot change the grit every time I want to SB!!

So …. what would be perfect size grit for decorative pictures and for my 3 level 3D effects? Appreciate your help, thanks.

@Brenda, it really depends on the thickness of the stencil and one’s preference/desired texture. A lot of times, I will use a finer grit such as 150 for 3 level sandblasting, so I can use an inexpensive thinner stencil. But usually, around 80-120 is preferred for those deeper etchings.

Are there ways to produce a smooth results when filling in larger places with dremel bits?

Hi.

Can I use any kind of stencil material for etching glass? I can’t find the pattern ,so I want make my own.

Thanks

@Sherry,

For the most part, yes, but if the stencil has tacky adhesive, you may have trouble pulling it off or use a solvent to remove all the adhesive from the glass after.

Also, if you are sandblasting, then you have to make sure you use a thicker stencil, depending on how long you blast it and the pressure.

Hello,

I have a small compressor which i bought from California air tools the ultra quite compressor which is oil free. I was sandblasting glass using silica sand and after completing three 12*12 glasses the rubber pipe which connects compressor and gun keeps coming out after 60 psi. i have tried tightening it up but its not working.

@ Huzaifa, you might have to show me a picture. I am guessing you have a siphon set up, but you should be able to use another hose clamp.