So I have been getting into a lot of fun things lately and recently experimented with my new low cost vacuum on-site sandblasting kit which was inspired by Barry, a fan.

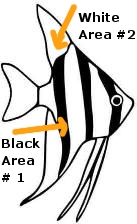

I tested this on the scrap piece of glass today because I was perfecting the equipment and I figured it would be great to share this 2 layer technique tip. If you don’t known what this is, it’s simply the 2 stage sand carving process. The photo shows below what it looks like which gives off a stand out look.’

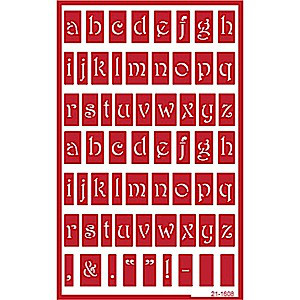

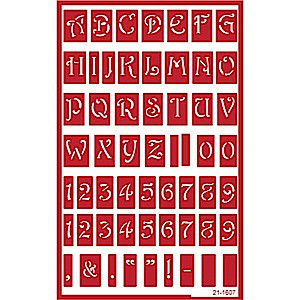

But I have never heard many people using this technique for letters so I thought I would share the ideas plus give some tips. First I sand carved deep into the glass for the first layer. Then, an outline of the letters were cut and lightly sandblasted. It’s best to use a smaller abrasive grit though for the last layer. I used a grit that is probably equivalent to 220 with an additional small sandblaster like the ones here.

Anyway the grit was originally 180 but after many uses, that stuff really wasn’t cutting well and probably broke down to about 220 (I’m guessing). Most people might throw it out, but it works great for light shading and to lightly etch the last layer. I hope you liked my tips. Please leave a comment below and any tips you might have. Thanks

Share this on social media or email by clicking below!

I was just thinking about this vac setup you have. Have you tried any commercial projects with it Eric? Looks like a neat idea. Just a word on the Pasche air eraser. I was haveing quite a lot of sputtering and stopping with it, so I plumbed into my my 100 lb. pressure pot. Can you say “Holly $h!t. Does this thing every perform nicely. It’s got a nice wide spray as it carves through the glass.

I haven’t been doing any commercial projects, but I know it works just like those high priced ones.

Sounds like a good idea with the Pasche. I thought about giving that a try.