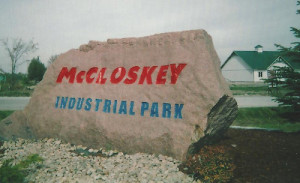

Here a huge landscaping boulder was converted into a sign for an industrial park. It was sandblasted and painted on-site.

He provided the below information and more photos below (click photo to see larger version):

Hi Eric

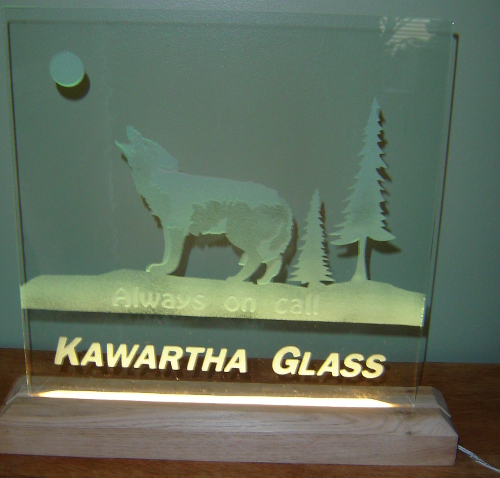

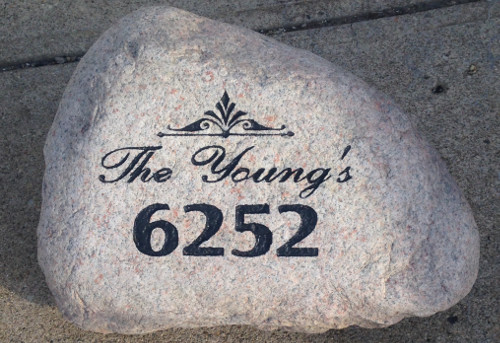

Great to see what other people are blasting. Lots of variety. Here are a few more signs that are blasted in stone.

Some of the larger ones weight several tons, so they are blasted and painted right on site with a 100 HP diesel compressor. Gets it done quickly.

Keep up the good work.

Ross

This landscaping rock was completed for a Holiday Inn hotel with their branded logo. Very cool and the painted colors look good!

Ross shared this photo which appears to be showing how he masks the rock with a stencil and a what appears to be a heavy duty plastic sheet on the outside for overblast.

Thank you for submitting these designs, Ross! It is great to see. If others have questions for him, please leave them below.

Share this on social media or email by clicking below!

Hi Ross, my question is “How do you get the (vinyl?) resist to stick to the rough surface of the boulders you’re working on?” I have sandblasted slate and even that flat surface is a pain to get the vinyl to stay put. . I’m impressed with what you do but as I have a large compressor there’s no way I could transport it to the site!

Awesome

Nice work, and Patrick i use a pre glued vinyl and spray rock with a clear gloss lacquer before applying stencil.

I do a lot of pavers I use 3M super 77 multipurpose adhesives. Holds good

Belo trabalho.

Qual a pressão do compressor para fazer este tipo de trabalho.

@Patrick,

I also used 3M super 77 like Lee does. I like Danny’s idea. I will have to try that.

Awesome

Very interesting I like it

AWESOME WORK

awesome

For very uneven boulders there are levelers you can use to “smooth” the surface some. You may want to coat the surface with something water soluble like white glue (the school glue) or even hair spray. This way the adhesive or glue you use will clean off the stone and will reduce the need to ice down your elbow after scrubbing for hours. The barrier will help with some stones where the resist does not adhere properly to the stone due to being grainy, powdery or slippery, this also prevent bleaching or splotching the stone that some adhesives and glues can cause. When in doubt, place an adhesive backed resist or glue in an out of the way area and give a little test to see 1. if it sticks well to the stone 2. does it clean easy 3. did it stain or change the surface of the stone. Only have time for a quick reply so I hope this info helps a little.

What grit is best to use on the stones and what air pressure should one use.

Depends on what you are doing. small fonts on a smaller stone or large ones like what is shown on this page. Stones have different hardness depending on what type they are. Generally the darker the stone the harder it is. It’s an interesting balance because you want to get the job done as quick as possible but you have to know how much abuse your resist can take before failing as well as how the grit bits into the stone. The larger the grit, the rougher it looks. I personally like 70- 80 grit Aluminum Oxide (I have used 60 grit as well on softer stone just fine) and I use 75 up to 90 PSI. It’s all a dance. Some stone like the hard punk rock style and others like the soft rock and need a gentle touch. Of course these descriptions are exaggerated and depends on how much detail you are trying to create. Large letters are much more forgiving. Have fun! Keep on Keeping on!

Hi Ross, I appreciate you work that you have made landscaping boulder into Sign for an Industrial Park.

Anyone try vacuum blasting? I’m looking to by a blast and vac from empire but sceptical if it would work because the nossel is so close to the stone, generally I stay 6 inch away.

Anyone here ever try vacblasting?

@ Scott, I have made my own which connects to a pressure pot (instead of a siphon system which most units are) and wrote plans on it. If you make your own, you can easily configure it to be farther out.

I also have information on these here: https://www.glassetchingsecrets.com/blog/dustless-on-site-blasters/

I have a question we got my parents a ston craved with there name on and address I want to no if you can change the name on it both of my parents have passed away and now I live in the house now and I got married I would love to keep it just change the name.

Yes it can be changed. The old lettering can be ground off. It takes some work but it can be done. I have done it several times.

So I am looking to try sand blasting a huge rock in my front yard since no stone carvers in my area. Where do you find someone that can make your rubber stencil. All I can find is you need to purchase the printer, some one out there make stencils

Jim

Thanks for posting the information on stone.

I’m trying to carve bluestone and having trouble getting stencil to stay on.

What size nozzle do you use for the large stones with lettering?