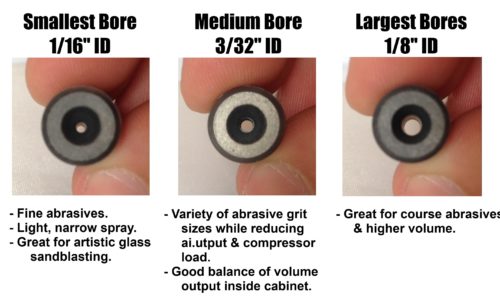

- 1/16″ ID Bore: Smallest inner diameter known to produce narrow sandblast streams. These are favored by those that do shadeblasting art, etching glass with the photoresist stencil process for halftones or just to reduce the output on your compressor while blasting a fine grade abrasive grit.

- 3/32″ ID Bore: Probably one of the more popular sizes with sandblast etching or general use inside cabinets. This mid-size inner diameter is great for many abrasive grits and the perfect balance to handle light blasting to deep sandcarving.

- 1/8″ ID Bore: Largest inner diameter we offer that produces a larger volume output which is great for larger projects or sandcarving boulders. Size is more ideal for general sandblasting projects outside a cabinet such as car restoration environments.

Why Carbide Nozzles Are Important For Us Sandblasting Glass Artists

When I first started, I went the cheap route and used ceramic nozzles. But they were such a hassle and the quick wear which enlarged the inner diameter immediately puts a strain on your compressor and prevents you from having a strong output pressure. That lower output pressure also makes sandcarving take way too long!

Using a carbide nozzle is almost a necessity for us that sandblast glass because we use very hard abrasives such as aluminum oxide and silicon carbide. Carbide nozzles are the only type that will hold up when using these abrasives. When you do the math, carbide nozzles actually reduce your overall cost since the cost per hour is less than using ceramic nozzles.

So it is important to at least use one of the carbide types such as: Tungsten Carbide, Boron Carbide or a Composite Carbide.

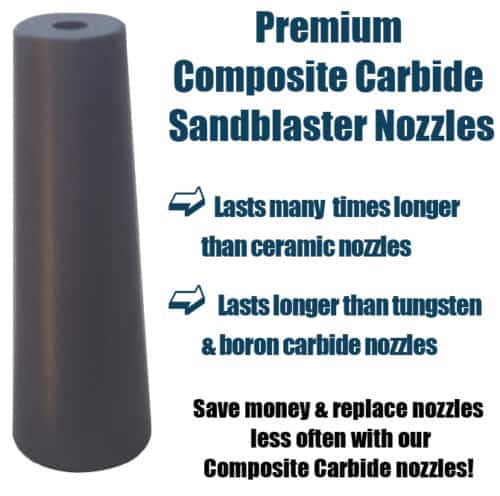

Our Composite Carbide Sandblast Nozzle Tips vs. Tungsten & Boron Carbide

I have collaborated with a factory to released our own composite carbide tapered nozzle and I’d like to give you the option to try it out. While I do not believe it is as good as the ROCTEC, these are offered at a much lower cost and I believe will be one of the highest valued nozzles available in the marketplace. We believe it will have the lowest cost per hour of use.

Our Nozzle Details

I am very happy with the production of these new nozzles. Some of the benefits:

- High density carbide which weights about the same as the ROCTEC.

- Typical tapered design used by most pressure pot sandblasters. (See dimensions on listing)

- Made of top of the line composite carbide.

Special Gift & Ordering

For this product launch, I would appreciate if you could try it out and share your feedback. For your feedback, I am providing a limited time 40% off discount for trying it. To get the discount, copy and paste the following code before checkout (listed under Discounts/giftcards section): 40offcarbide

These are also backed by a 100% Satisfaction Guarantee. I encourage you to please contact me if you find it not to last as long as you thought. I will refund your order so there is no risk.

This is my way of thanking you for testing these out for me. Any feedback helps me improve it and continuously tweak the formula, if needed.

Remember to copy and paste the above code at checkout. There will be a box called promotions to enter this.

Have a question or feedback on these? Please leave it in the comment section below. Thank you!

Share this on social media or email by clicking below!

WHERE IS THE 40% OFF CODE ?????

Yikes! I forgot to add it and was rushing here. The coupon code is: 40offcarbide

I am so sorry about this. I am updating the post with this info now.

So I already bought the nozzle. Do I get a refund??

@Rodney, yes I can work with you on that. Please email me about it. Thanks

what gun will except this type of nozzle? Where can I buy one? I currently use a nozzle that’s straight 1/2″ OD and 3/16 ID. Would like to try your smaller ID nozzles hoping to reduce needed CFM @ 80 PSI.

Hi … are these nozzles for sale yet? And are you sending to Norway?

Help! I have a Etchmaster Siphon Sandblast cabinet that uses Type 2 Glastar nozzles. I have been on hiatus from Sandblasting for quite a time. And now I am searching desperately for replacement nozzles. Can you help me?

Thank you