My plans show how to make the much desired type of sandblaster: the pressure pot.

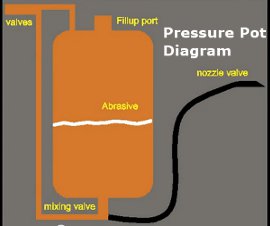

As you may know, the pressure pot allow us:

- to create sandcarved dimensional artwork in glass with its higher pressure in comparison to siphon blasters

- to engrave rock with its high pressure which is required

- to increase the efficiency and reduce wear on your compressor

Pressure Pot Plans for the Glass Etcher/Sandcarver

Pressure Pot Plans for the Glass Etcher/Sandcarver

Many of us that sandblast glass prefer to modify the manufacturer pressure pot equipment by using smaller hoses and nozzles to get a more precise abrasive stream. This allows them to have better control for artistic glass blasting. Plus this reduces the unnecessary waste of overblast since most glass projects are smaller.

My sandblaster plans are catered to the glass blaster with instructions on how to make a less cumbersome hose and nozzle system. However, you may desire to use a traditional large blasting hose which can be easily made from the plans as well.

Benefits of Making a Sandblaster vs. Buying a System

Some of the pressure pot systems available today are becoming more affordable but as many of you know, there can be some issues with abrasive flow.

1. Get Better Abrasive Funneling

1. Get Better Abrasive Funneling

I have discovered one of the reasons these low cost sandblasters sold have this issues is because the tank inside is rugged. The abrasive tends to bind up on the sides of this rough surface so much of the abrasive isn’t funneled down toward the hole. That is why many of these require you to shake the tank to get abrasive to come out the nozzle.

My sandblaster plans, help solve this issue for the most part, because my guide shows how to make the tank out of old propane tanks which have smoother walls inside. It talks about where you could easily get these tanks free and how to safely tap into it (IMPORTANT: PLEASE READ PAGES 5-6 BEFORE ATTEMPTING).

2. Make Bigger Pressure Pot Sandblasters

One of the great benefits to make your own is you can make the tank as big as you want too. You can select from 20 lb, 30lb, 40 lb, 100 lb or even 120 gallon propane tanks.

You can purchase larger industrial pressure pots but many of those can cost thousands of dollars. If you are able to find either an old free tank or a low cost tank, you can make these yourself fairly easily if you are mechanically inclined.

A bigger tank allows you to fill it with more abrasive so you do not have to stop as often to refill it.

Where to Get the Sandblaster Plans

A while back, I published these pressure pot sandblaster plans on my other website. Someone was recently asking where they were on this site so I decided to make them available for ordering here as well.

You can now read more about these and order them through this site here.

Share this on social media or email by clicking below!

Pressure Pot Plans for the Glass Etcher/Sandcarver

Pressure Pot Plans for the Glass Etcher/Sandcarver 1. Get Better Abrasive Funneling

1. Get Better Abrasive Funneling

Hi Eric, Could you please let me know how to choose a compressor? I want to do half tone portrait photos on wine bottles. I am currently looking at 24L Silent Oil Free Compressor 0.55KW 220V / 50L Silent Oil Free Compressor 0.75KW 220V or 50L Silent Oil Free Compressor 1.5KW 220V this one has two compressors on it. They all have a water filter and are targeted for the medical profession or should I be looking at something else.

Do you still have the foot pedal kits available for purchase or only the designs?

Todd, I occasionally do upon request. The reason I stopped offering these to the public is because they aren’t in a large demand and so they are very home made looking. Not sure if folks mind that but those are the reasons.

@Ken, if you are using a pressure pot system, please look at this chart for some rough guidance:http://www.sandblasterinfo.com/air-compressor-chart/

Would you be up for making a pedal kit? I bought your ebook and while everything is easy to follow its a time thing. It makes more since to pay to have it made than build myself. Email me one way or the other lol

@Todd, yes I can and thank you for the interest. Can you confirm you will be using it for a pressure pot blaster? There may be a delay of a week to get it to you.