I am happy to post about Glenn Kelley. He is sharing a few samples of his sculpted etchings known as sandcarvings which were done on acrylic glass and provides his story on how he got into business doing this. That is always interesting to hear! He shared the below:

This appears to be a 2-stage sandcarving of an Indian riding a horse with a spear, etched on acrylic glass and light up with a blue light! These can be fun because you simply etch the a line pattern deep, then etched the rest.

This sandcarving has more layers know as multi-sandcarving. This depiction of an eagle’s head of course takes much more time but they are fun to do!

We started sandcarving items as Christmas presents almost two years ago. We found your website very informative and took it from there. In January of 2014 we opened our sandcarvings business and have really enjoyed it thus far. Our customers have pushed us along the way to where we are now. We have etched Crystal, Glass, Granite, Marble, Stainless Steel, River Rocks, Wood, & Acrylic. Lately we have stepped up from one shot etching into mult-shot sandcarving. We use 4 mil vinyl for most of our stencil material but have also gotten into using 3 & 4 mil photo resist for more detailed projects. We use 180 grit Aluminum Oxide with 30-45 psi and a 3/32″ nozzle. We have two pencil systems that are portable and a large pressure pot system that we use most of the time. You can see samples of our work on our Facebook page.

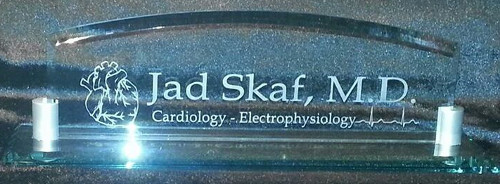

Here is another etched acrylic glass but for a name plate to be used on an office desk. This is a great business idea, especially for doctors. I loved the graphic details in this with the heart and pulse line.

Share this on social media or email by clicking below!

How are you cutting the stencil or are you using a photoresists technique.

We currently are using a Silhouette Cameo vinyl cutter. All of the pieces shown where stenciled using vinyl.

Iam just a begginer I need all the help I can get i love the way it looks. Beautiful

Thank you

what is the equipment and substrate you’re using?

Awesome work

what psi & cfm were used ?, Which gun is good to buy

Kevin,

We use 4 mil vinyl as much as we can. For more detailed images we use 3 & 4 mil SR3000 photo resist and 3 & 4 mil RapidMask photo resist.

Ratilal Vadhavana,

We use a couple of pressure pot systems. The pencil system we shoot at 30-45psi at 1.5 cfm. The big pressure pot cabinet we shoot at 30-45psi at about 6cfm using a 3/32″ nozzle.

What type of vinyl would you recommend to carve rocks? I’m just setting up a system and I am gathering all the info I can. I will be cutting out by hand at first. Maybe I’ll get an auto cutter in the future. Thanks for the info in advance!

Shawn,

We use Oracle 651 vinyl for glass, crystal, metal, granite, marble, pavers, & river rock.

Respected Glenn Kelley

I have air compressor, I want to buy Penblaster & pressure pot & Sandblasting cabinet which company sells it, can you please guide me

Appreciate your previous answer

Thanks

Ratilal

Ratilal Vadhavana,

Our blasting cabinet is made by R ayzist and the pencil blaster is a Pro Blaster made by Varnim Company in California.

Ratilal Vadhavana,

Our blasting cabinet is made by Rayzist and the pencil blaster is a Pro Blaster made by Varnim Company in California. Ikonic Imaging also made blasting cabinets.

Thanks Glenn Kelley, appreciate very much

Thank for showing you work it is great

Antonio Gomez,

Thank you!!!

I have an opportunity to buy a Graphtec CE-6000 Vinyl hardly used. Would this be a good vinyl cutter to buy for making sandblast stencils?

I am into sand carving but have not really done multiple sand carving, wish to learn more. Great work

Just thought I’d pop in here real quick. First of all, Glenn that is some impressive works of art. I too do engraving, but not yet the sand carving. For those looking at getting into this, a good vinyl cutter is a necessity, and you can get them from UScutter.com. Much like Glenn, Oracle is a great vinyl, we use 3 mil all of the time with no blow through. This can be had for less than $0.75 per foot at UScutter as well. I just changed from using the pressure pot blaster to a siphon feed one, in hopes of creating a self contained unit that will vacuum up the debris once it leaves the glass. No mess, work less! As for the media, I have been using Glass Beads 180 grit, which works well for frosting the glass. I have an air brush blaster which uses 220 grit carbide, but find that media very expensive and hard to get. Great work Glenn. You can see a few of my own designs at RogerAndDave.com

Jay,

Any good quality vinyl cutter will work. I looked at the specs on Graphtec CE-6000 and it looks like a really nice cutter.

Nnamdi Agomog,

Thank you for the kind words!!!

David,

Thanks for the information and the link to your website. We also purchase from US Cutters for some of our supplies.

Respected Glenn Kelley & David

Which air compresor with how much Hp, PSI & CFM you use at what settings, I have Silhouette Cameo to cut stencils, I have 2 Hp California Air compressor with dual tank of 4.6 gallons, it has 7 cfm at 40 psi & 5.3 cfm at 90 psi, is it okay or I need to change it, still I have time I can return & get one as per your suggestions, Thanks for nice guidance & help, appreciate, I also have TEKTON sandblasting kit, I also have Mini Air eraser which uses 65 psi its nozzle diameter is 0.5mm, it has 15 cc cup, its gravity feed, I have vinyl from US cutter, as I was unaware I ordered 8 mil, now will buy 3-4 mil, Its required higher settings of blade to cut it in Silhouette Cameo, Thank you all, Have a good day

Ratilal Vadhavana,

I find it best on the Silhouette Cameo to use the high tack cutting mat, set the blade to 2, pressure at 6, and speed for 1 to 6 depending on how much detail is on the design. We use the Oracle 631 vinyl 12″ width from US Cutter. I use an ultra quiet California Air compressor for my smaller blaster and I use a 30 gallon compressor for my big box.

Thanks, will my 4.6 gallon ultra quiet California Air compressor be good

what grit do you use etching glass

Yes that will work just make sure that you have a good in-line moisture trap installed.

Dinah Kern,

180 grit Aluminum Oxide.

Great job! Is ther a place I can get steccils cut?

Jon Mallory

There are places on the web that you can get custom stencils cut however I have found them to be quite costly.

Rayzist has stencils of patterns that you can purchase from there website.

Thanks Glenn Kelley, I have purchased moisture trap from Home Depot, some people say its not good quality, will it if needed will change it, Once again thank you very much, for very nice guidance

For those wanting stencils cut, I may be able to provide that as well. But if you plan on doing this stuff long term you really should look at USCutter’s MHK2 12″ Vinyl plotter. It is money well spent! I run my pressure pot at 20 PSIg which is more than enough, however you need to be able to run 90 PSIg to use a siphon unit, to pull the media to the gun. One lesson about air compressors, they are all designed to run only 75% of the time without overheating and causing damage to the heads. Much like a car, if you run it long enough without proper cooling, it will warp the heads, the top of the compression cylinders. One way to do this, is to shoot only after the compressor is finished reloading, and stop shortly after it comes back on again. The compressor itself, should always run full pressure, that is what keeps the rings seated. The rings, again, much like a car cylinder is what compresses the air. So down line, near your point of taking the air out, you need a regulator to bring it to the lower pressures needed for blasting. As Glenn stated, a moisture relief bowl is a necessity, as wet media will only clog the tip you are blasting out of, and possibly cause a brick of media in the chamber.

Really wonderful. All the luck for the future.

Hi Rameshbhai, Happy to learn that one more Indian is here on blog, I am from Gujarat, Right now in USA, What type of work do you do

Exquisite work!!

Suoer great info my friends i learned from all of you i am a soldier and pic up this great past time i am curing my own stensils by habd and is hard also buying a 60 gallon 12 to 14 cmf compresor with a iconiks cristal blaster i will love to learn more from all of you