I am trying a few different types of vinyl when I sandblast my mugs. And I have to turn the pressure way down on my cabinet. It is taking a long time to sand blast and was not sure if you had some suggestions on what type of vinyl to use. I tried the vinyl it said in secrets to glass etching book an it did not seem to work. Maybe something a little thicker? Not sure, any help would be greatly appreciated. Thanks.

My Answer:

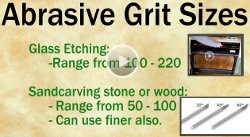

If your talking about the removable Oracle brand that I talked about, its only three mils thick. You have to use a fine grit to sandblast at higher pressures. I use a 180 grit to blast with this vinyl and sometimes I’ll even carve fairly deep with it.

For a guide, as the grit becomes finer, the thinner the vinyl can be and the higher the pressure can be use without penetrating through the stencil. Another thing that you can do (I do this every once in awhile) is double the vinyl up before you cut it. Its not too hard either. I talk about in this in a comment on my blog about the decoration designed etching: glassetchingsecrets.com/blog/decorationdesign/.

Share this on social media or email by clicking below!

Try Anchors stencil no 128. It has rubber in it so there are good bounce for the sandparticles. You may have to use 3m,s sandblasting filler to avoid blowouts. I use it to carv in the glass as deep as 15 mm. The sand I use has 100 my, so it is very fine. Good Luck !

Thanks for the resource Peter, your awesome. I enjoyed looking at your work!

Whoohoo! This is exactly the information I was looking for. It’s so hard to get into sandblasting glass because there just does not seem to be a lot of people who can do it and do it well!

Eric this is jo anne I’m want to no how thick do u need the vinyl to sandblast a river rock and how close do u need to be and do u need to tape the stencil off

Joanne, it really depends on a lot of things: how fine/course the abrasive is, how high of a pressure you are aiming to get it completed quicker, how soft but durable the vinyl is and even how cold it is. Overall, you should do a small test to get a feel for the combination of materials you are using. Hold the nozzle far back at first and slowly move it forward until you have a good cutting rate while pulling back once it seems like it is starting to tear up the vinyl.

In a nutshell, you should probably aim to use a minimum of a 6 mil thickness, and that is if you are not cutting very deep and have finer abrasive. I like to use around 150 grit because it allows me to get away with cheaper, thinner vinyl

I bought several reusable stencil for sandblasting, The stencilsare green, but the image are white. Hoe can I used it??? Just put tyhe stencil over the bottle and sand blasted or I have to throught the images lines and cutter by hand

Angel

Which of this mil of thickness is best to use on glass and river rock 8 mil or 12

@Joanne, either one will work, but lean toward the thicker if you plan on doing deeper engravings. thanks

Is glass bead good to use on glad etching

Glass bead isn’t typically used nor recommended. From what I know of glass bead, I don’t think it is sharp so it may not even etch. However, I have never tested to see if it will etch. Crushed glass may etch a little but do a poor job.